RazorGage Machine Control with Allied BIM Fabrication Desktop

Fabrication Desktop enables model-to-machine workflows from all design software to cut linear lengths directly on ALL RazorGage Machines.

Allied’s Fabrication Desktop is second-to-none in enabling model-to-machine workflows to RazorGage machines from CAD/BIM. Seamlessly connect your model to the RazorGage machine to enable cutting, assembly instructions, installation instructions with 3D Spools and inventory management.

Cloud Cut List Enabled

Publish, Track, and Communicate cut lists to any machine in the world. Gain insight into what is cut and when the job has been completed.

Dynamic Pack Optimization

Eliminate raw material waste with dynamic pack optimization (nesting). The operator can simply load the cut list and sort by sizes to yield the least amount of waste using Allied’s state-of-the-art optimization algorithm.

Easy Labels

Label each part individually with part numbers, lengths, QR Codes, project, and assembly numbers. Stop fighting labels and make your label nightmares a thing of the past with EASY Labels.

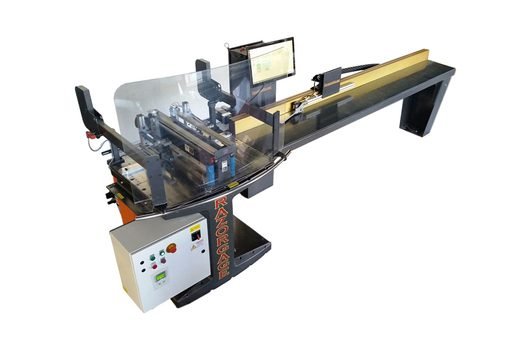

SOFTWARE FOR COMPUTERIZED SAW SYSTEMS

Everyone uses personal computers these days. Why should your automatic saw measuring system be different? All RazorGage computer controlled saw systems include a reliable graphical user interface with built-in Wi-Fi.

RazorGage offers computerized saw positioners with either Android or Windows 10 Professional interfaces. Both platforms offer intuitive operation that nearly eliminate the need for training. Parameters have sensible names like SPEED, KERF, ACCEL, & DECEL, so you don’t need a manual to understand the settings. Most operators can figure out the saw optimization software with just a few minutes of practice.

With superior software and advanced hardware, RazorGage systems are equipped to handle any job with ease. Learn more about RazorGage products and the software that powers them.

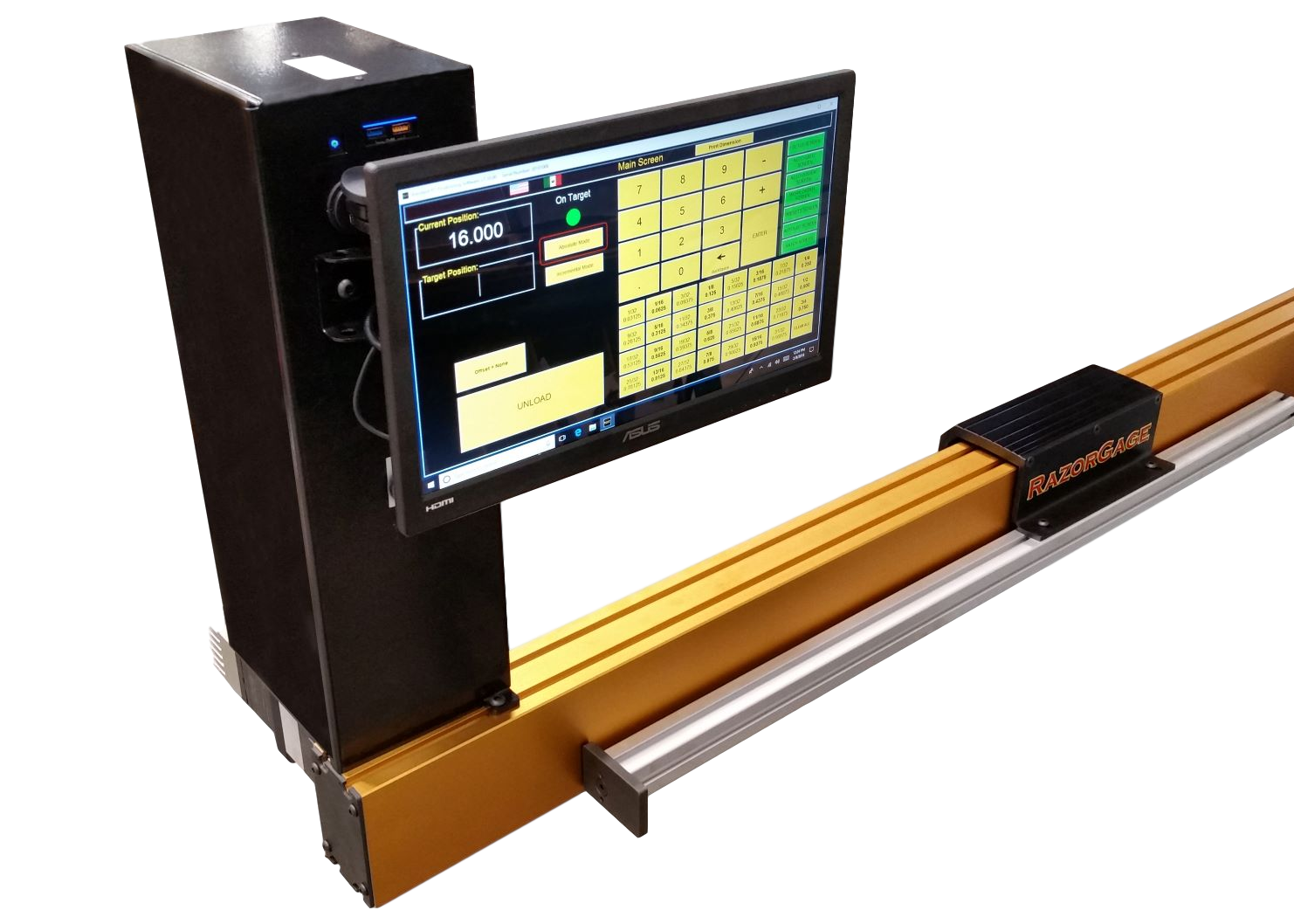

WINDOWS PC SAW OPTIMIZATION SOFTWARE

The Windows computer controlled saw software provides a bright, bold user interface. There are no menus to memorize. Operation is obvious. Setup and calibration functions are just a screen touch away. Built-in functions such as fraction keys, pages of Presets, the Work Order screen, the Auto-Pusher screen and the Batch screen, help eliminate operator mistakes and improve productivity. Upgrade a ST-Windows platform to include AutoList at any time to optimize yield on your expensive material.

Networking and file sharing using the RazorGage software is no different than any other PC in your office, home, or shop. Since the RazorGage software is based on a rapid development platform, it is constantly evolving to meet the needs of our customers and can be easily customized.

To learn more about the screen functions available with the ST-Windows software, click on the different descriptions below, to watch a short video that shows what that function does.

Assign Infinite Offsets to picture buttons for secondary operations.

Our PRESETS Screen features four pages of 56 hot keys to which you can assign positions and labels.

The BATCH Screen is perfect for push cutting large quantities of same length parts.

Fraction Keys minimize key strokes reducing human error. Only 3 strokes to move to a position like 39-13/32.

ANDROID COMPUTERIZED SAW SOFTWARE INTERFACE

The Android’s interface makes operator input fast, easy and intuitive. Fraction Keys, Unlimited Hot Keys, and the cutlist screen with kit quantity multiplication and cutlist sorting features, make this entry-level interface a powerful ally in the fight to improve quality and productivity.

You can create your cutlists using the computerized saw touchscreen or send a cutlist over a WiFi network. The Android tablet has tremendous storage capacity, so you will not be limited to saving only small cut lists. Furthermore, the cut lists can be restored to original quantities after use or even multiplied should you want to make several “kits” of parts at once.

XT ANDROID HOMESCREEN

ST-A ANDROID HOMESCREEN

GETTING STARTED WITH RAZORGAGE SAW OPTIMIZATION SOFTWARE

If you’re ready to revolutionize your business operations, reach out to us today. A RazorGage computer controlled saw system will transform the way you work.